High Throughput with Parts up to 3500 mm in Size

In production metrology, it is important to identify, analyze and correct quality problems as fast as possible. Many parts are to be checked as completely as possible in order to be able to initiate corrective measures and minimize scrap at short notice and in a targeted manner.

In production metrology, it is important to identify, analyze and correct quality problems as fast as possible. Many parts are to be checked as completely as possible in order to be able to initiate corrective measures and minimize scrap at short notice and in a targeted manner.

Technology

High-speed scanning

The ATOS ScanBox models 6135 and 6235 are equipped with a safety control to be able to operate sensors with laser technology. Combined with the extremely bright light source of the ATOS 5X, both models allow high throughput with high detail resolution at the same time, which is required in car body manufacturing, for example.

The ATOS ScanBox models 6135 and 6235 are equipped with a safety control to be able to operate sensors with laser technology. Combined with the extremely bright light source of the ATOS 5X, both models allow high throughput with high detail resolution at the same time, which is required in car body manufacturing, for example.

Loading and measuring at the same time

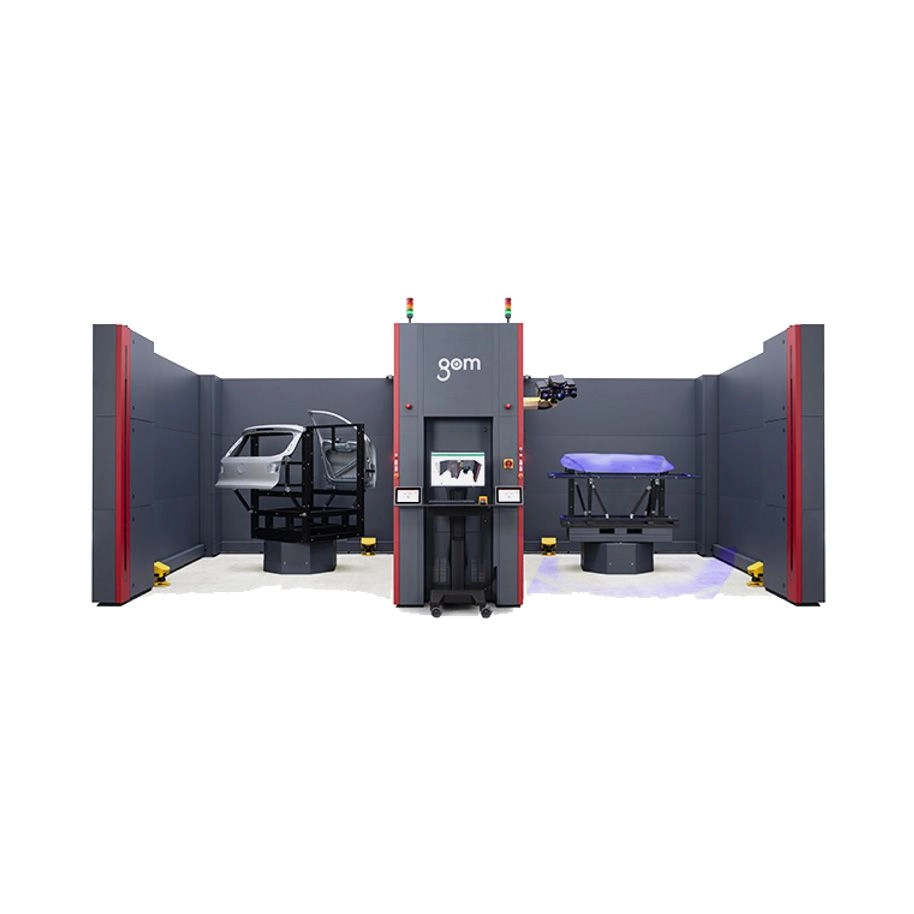

The ATOS ScanBox 6235 makes an even higher throughput possible due to two working areas that can be operated independently from each other. The rotation table can be set up parallel to the measurement. In both working areas or on the rotation tables of the ATOS ScanBox 6235, parts such as doors or trunk lids with a size of up to 3.5 m can be placed. Both working areas are operated safely due to the automatic doors.

The ATOS ScanBox 6235 makes an even higher throughput possible due to two working areas that can be operated independently from each other. The rotation table can be set up parallel to the measurement. In both working areas or on the rotation tables of the ATOS ScanBox 6235, parts such as doors or trunk lids with a size of up to 3.5 m can be placed. Both working areas are operated safely due to the automatic doors.

Very high load capacity

The ATOS ScanBox models 6135 and 6235 are constructed for large and heavy parts, for example, cast parts, attached parts or tools with a size of up to 3.5 m. The rotation table unit of the coordinate measuring machine carries parts with a weight of up to 5,000 kg. Depending on local conditions, the control tower of the ATOS ScanBox 6135 can be positioned on the left or the right side.

The ATOS ScanBox models 6135 and 6235 are constructed for large and heavy parts, for example, cast parts, attached parts or tools with a size of up to 3.5 m. The rotation table unit of the coordinate measuring machine carries parts with a weight of up to 5,000 kg. Depending on local conditions, the control tower of the ATOS ScanBox 6135 can be positioned on the left or the right side.

Inquiry - ATOS ScanBox Series 6 (High Throughput)